CG Thermal Impervite® LT impervious graphite tube is manufactured by subjecting a fully graphitized porous graphite tube to our state-of-the-art proprietary vacuum/temperature/pressure impregnation of modified phenolic resin.

By carefully measuring the resin properties and matching the characteristics of the graphite, we can guarantee a final product that consistently meets our mechanical, thermal and corrosion resistant standards. All phases of the impregnation process are computer controlled, recorded and archived verifying the manufacturing process is exactly per our specification.

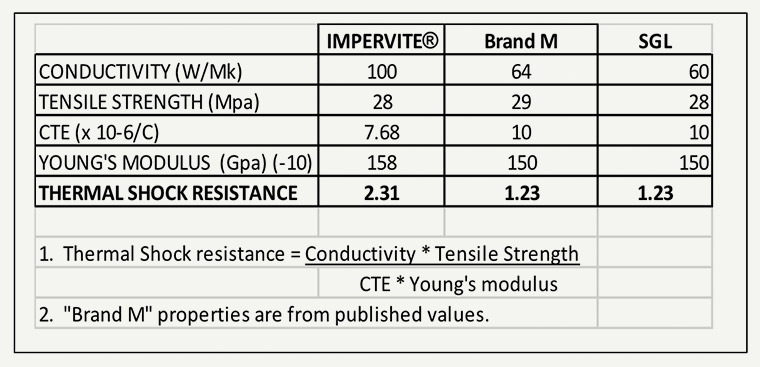

The result is an industry leading Impervite® LT graphite exchanger that meet or exceed all other phenolic impregnated graphite units in the very important exchanger properties of thermal conductivity, thermal shock resistance and thermal stability. The absence of carbon in our fully graphitized tube minimizes the brittleness while maximizing the toughness and fatigue resistance.

IMPERVITE LT. IDEALLY SUITED FOR HEAT EXCHANGER SERVICE.

- Highest Thermal Conductivity.

- Highest Thermal Conductivity.

- Exceptional Thermal Shock Resistance.

- High Toughness, Lower Brittleness.

- Low Thermal Expansion Rate.

- Exceptional Thermal Stability.

- Fully Graphitized.

- Excellent Resistance to Fatigue Stress, Resulting in Longer Operational Life

In order to reduce the cost of the unit, competitors have made the decision to supply their exchangers with a “graphite” tube that is not fully graphitized. The minimizing of the graphitization step lowers the production cost but results in a “carbon/graphite” tube which is not fully graphitized. The carbon content, in order to reduce the cost of the unit, competitors have made the decision to supply their exchangers with a “graphite” tube that is not fully graphitized. The minimizing of the graphitization step lowers the production cost but results in a “carbon/graphite” tube which is not fully graphitized.

The carbon content, because of itsinsulating properties, lowers the thermal conductivity, increases the thermal expansion rate, lowers the thermal shock resistance, and lowers the ability of the tube to absorb impact energy.